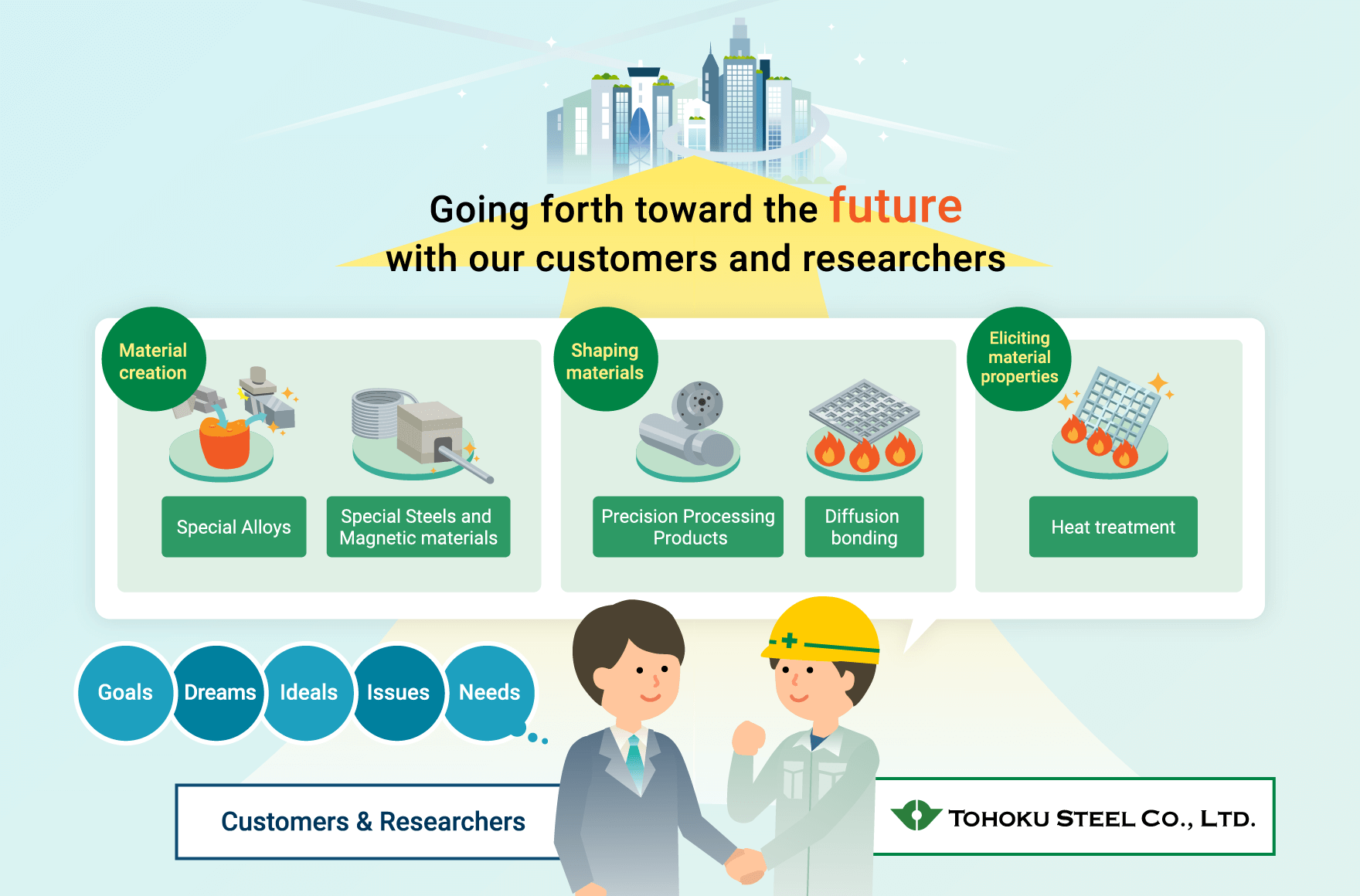

Tohoku Steel is an integrated engineering manufacturer that offers everything related to special steel from material development and treatment to heat processing.

Tohoku Steel Co., Ltd. was born in 1937, based on a proposal by Dr. Kotaro Honda of Tohoku University, a global authority in physics and metallurgy research. Ever since our establishment, we have commercialized numerous new alloys and technologies including mass production of heat-resistant steel and development of the world's first corrosion-resistant, soft-magnetic stainless "K-M steel" through collaboration with and guidance from research institutions such as Tohoku University and its Institute for Materials Research. We have also contributed to the development of industries in Japan and overseas through our strong market share (*) in heat-resistant steel for intake and exhaust engine valves in automobile-related components and soft-magnetic stainless steel for electronic fuel injectors. (* Based on in-house research)

Tohoku Steel is committed toward earning the trust of our customers, and will pursue new possibilities of special steel through a variety of ongoing research and other challenges, to promote the evolution of manufacturing, development of our lifestyles, and for the future of the earth.

What we do at Tohoku Steel