- Outline

- Strengths

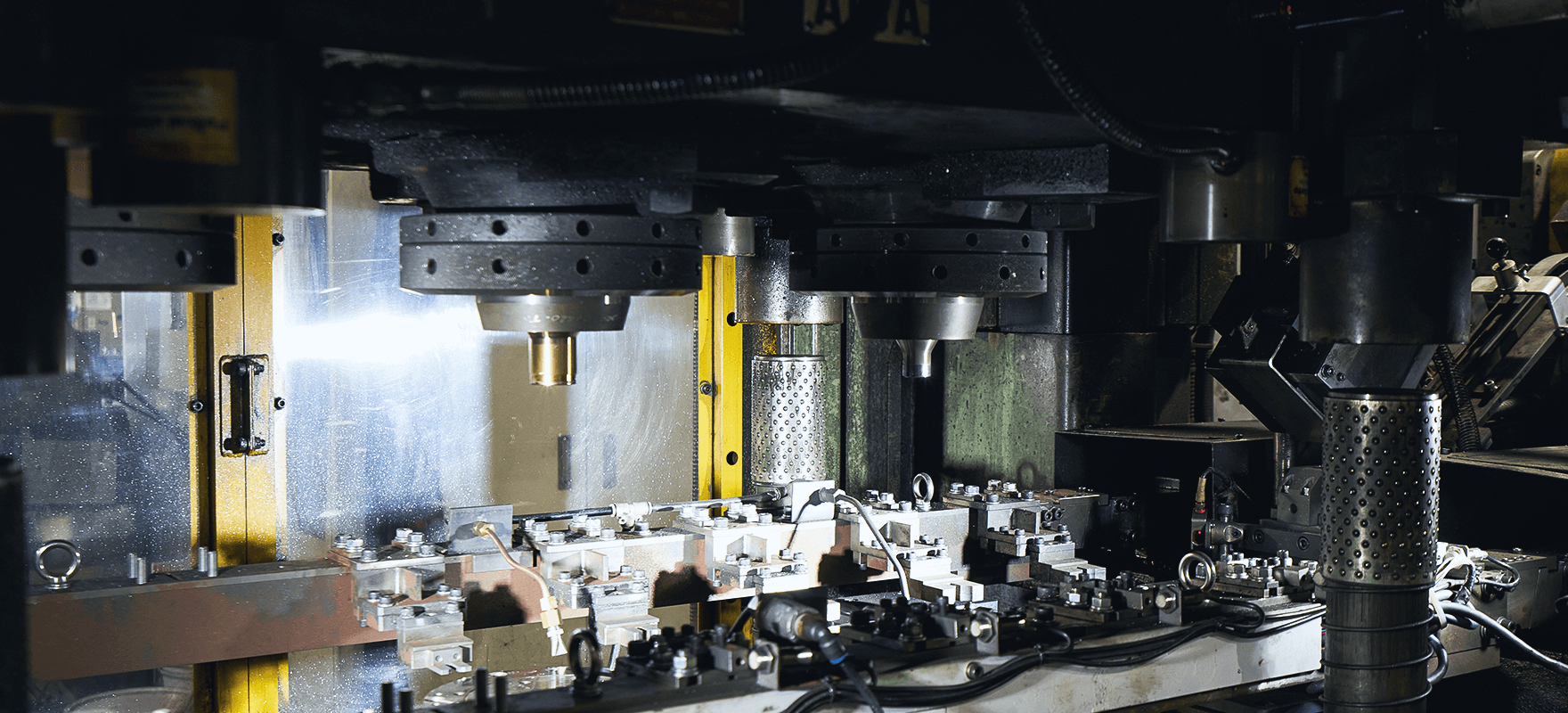

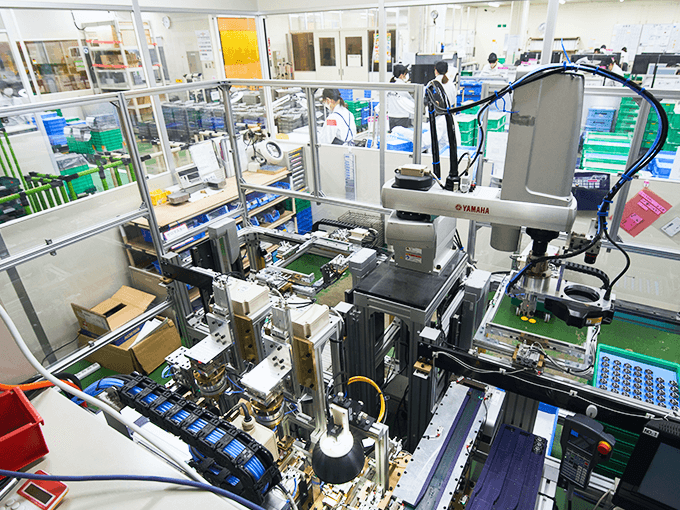

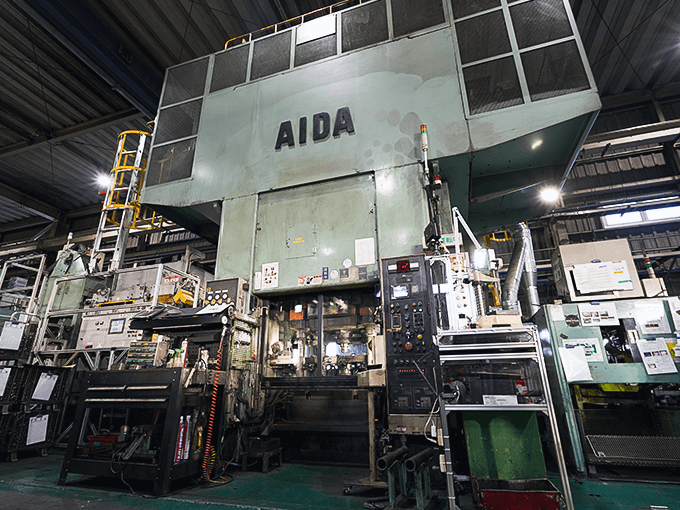

- Process flow / Examples of product processing / Main equipment

- Product Information

- Contact Us

State-of-the-art high precision technology realizes high yields.

We manufacture processed materials from the phase of melting, including material development. We also process parts using these materials. In particular, we pursue cost minimization through integrated manufacturing, which includes processing of precision rough shape materials by cold forging using difficult-to-process materials from cutting to heat treatment. We provide high quality, high accuracy parts to satisfy our customers.

Our strengths in precision processed products

With our processing and development technologies developed from our expertise in special steel manufacturing and material forging with reference to the shape of each part before cutting, we can significantly reduce the total cost (by approx. 40–60% on average) by implementing NNS (Near Net Shape). In addition, to provide high quality products, we implement a strict quality control system, including dimension and appearance checks through image analysis inspections that employ cameras.

Process flow / Examples of product processing / Main equipment

Flow from material development to maching process