- Outline / Strengths

- Characteristics of research and development

- Manufacturing dimensions / Manufacturing examples / Lots / Main equipment

- Product Information

- Contact Us

We can handle all types of orders for material development.

We perform material development in accordance with customers' needs, analysis of materials and parts, and small-lot manufacturing of samples for prototype evaluation. Our customers highly evaluate our development and manufacturing of magnetic measurement equipment by applying magnetic circuit technology and other magnetic application products (the Equipment Development Group).

Characteristics of research and development

In order to address smoothly customers' needs for development of materials and products, we make integrated efforts to develop materials for melting in small quantities as well as manufacturing and sales of small-lot products for prototyping and evaluation. Especially in the case of small-lot manufacturing of samples for prototype evaluation, we can provide samples in appropriate quantities at appropriate prices using our small 1-t and 7-kg furnaces.

Manufacturing dimensions / Manufacturing examples / Lots / Main equipment

Product Information

Tohoku Steel provides a wide variety of materials including magnetic materials, heat-resistant alloys, anti-corrosion alloys, low thermal expansion materials, electronic materials, base materials for deposition, and sealing materials. We can also deliver unique materials in small lots in accordance with customers' needs.

New alloys / New technologies

■Process

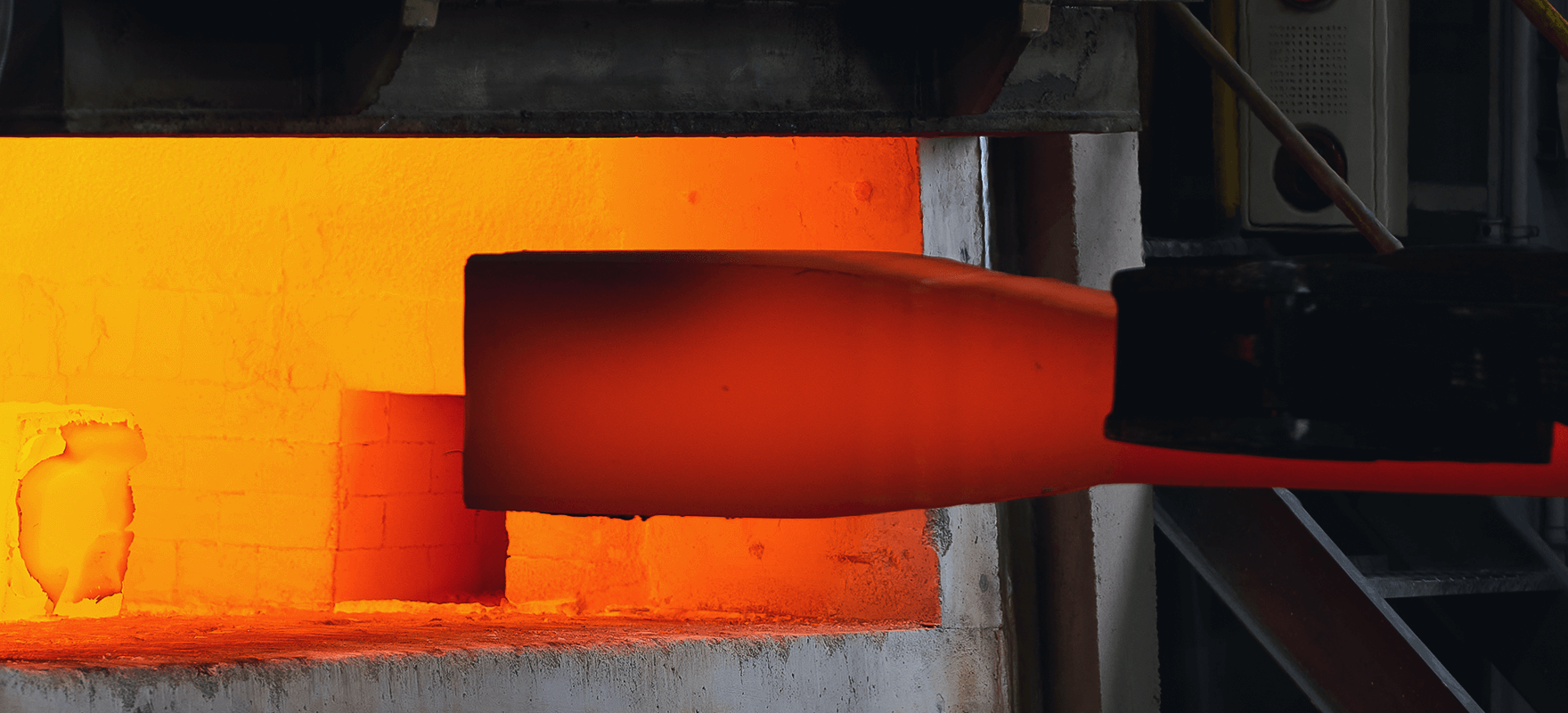

[Melting]

- From ferrous metals to non-ferrous metals with a cobalt, nickel, or copper base, we provide special alloys (magnetic materials, heat-resistant alloys, anti-corrosion alloys, low thermal expansion materials, electronic materials, base materials for deposition, and sealing materials) having various compositions.

- By mixing strictly selected raw materials and vacuum/atmospheric melting, we can narrowly control material compositions, which is particularly necessary for functional materials.

- By performing high vacuum melting/refining, which is difficult to do in large vacuum furnaces, we can manufacture clean alloys with a low level of gas components.

- We can provide ingots in square or circular shapes as well as various sizes to meet a wide range of customer needs.

- We also handle materials beyond those mentioned in the examples. Please feel free to contact us for details.

[Forging]

- We forge materials provided by customers as well as perform integrated manufacturing from the melting to forging processes.

- We can manufacture square, circular, and rectangular shapes having various dimensions.

- We can also handle dimensions other than those mentioned, so feel free to contact us.

* If the customer provides the base material, the single weight of said base material shall be limited to one ton or less.

■Development / Testing

We have cultivated and accumulated unique technologies from our many years of development and manufacturing of new characteristic materials under the guidance of and in collaboration with Tohoku University and other research institutes in Sendai. Based on this, we will assist you in developing materials.

[Material development]

We improve the functions of existing materials in accordance with customers' requirements. We assist customers in developing new materials and other tasks.

Generally, we perform material development tasks under nondisclosure agreements.

The Technical Division is responsible for development tasks related to heat-resistant steel and soft-magnetic stainless steel.

■Delivery time

Although delivery times vary depending on when we receive orders, generally speaking we can have the cast material delivered in two weeks to a month, and forged ingots can be delivered in a month to a month and a half.